Article: Fatigue strength

Strength test rig

| Location | Minden, Pionierstraße 10 |

|---|---|

| Operation | Strength and function tests for components of vehicles and permanent ways |

| Equipment |

|

| Testing conditions |

|

Lennart Ruberg

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY

Bogie frame test rig

| Location: | Minden, Pionierstraße 10 |

|---|---|

| Operation: | Bogie frame |

| Testing conditions | EN 13749 |

| |

| Equipment: | Load portal and freely selectable load force supports |

Lennart Ruberg

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY

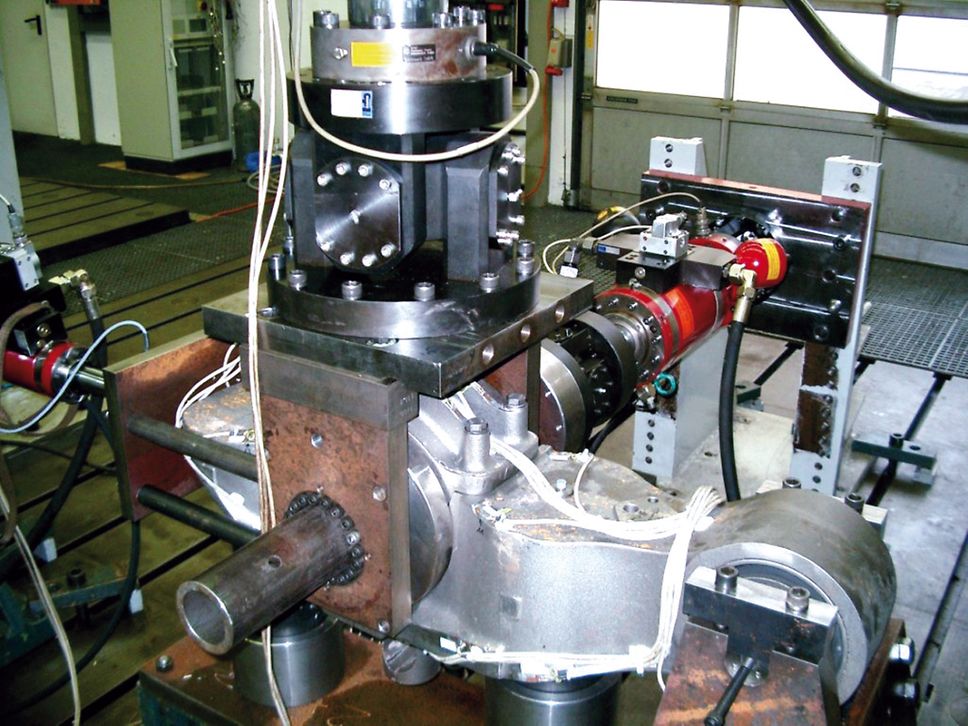

Rotational bending fatigue test rig

Location | Minden, Pionierstraße 10 |

|---|---|

Operation | Fatigue resistance and crack progression tests on wheels and shafts |

Equipment | Prestressed bed with out-of-balance excitation |

Testing conditions |

|

Markus Kohn

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY

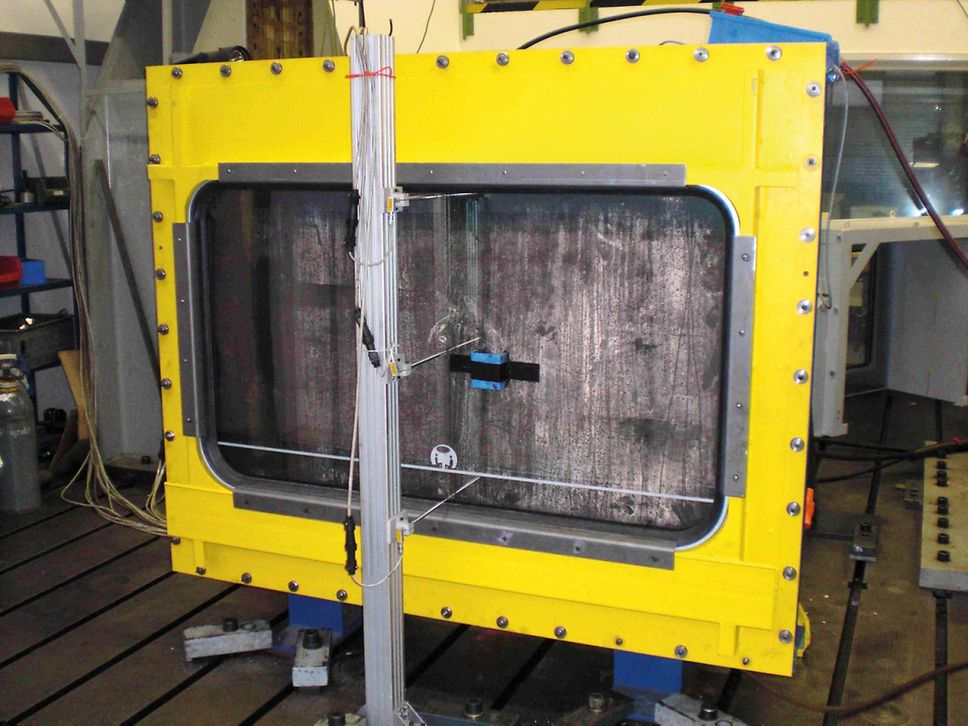

Window test rig

Location | Minden, Pionierstraße 10 |

|---|---|

Operation | All types of side window |

Equipment | Pressure chambers of different sizes |

Testing conditions |

|

Markus Kohn

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY

Axle box test rig

Location | Minden, Pionierstraße 10 |

|---|---|

Operation | Axle box |

Equipment | Test bed shafts with diameters of 120 mm, 130 mm and 150 mm |

Testing conditions |

|

Finn Wichelhaus

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY

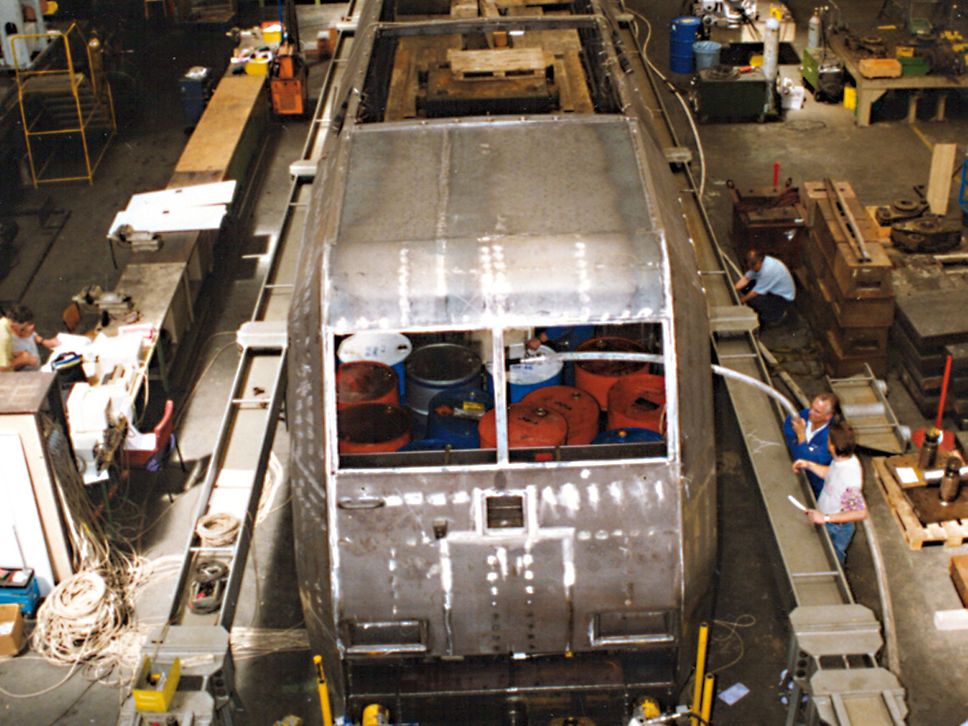

Pressure test rig

Location | Minden, Pionierstraße 10 |

|---|---|

Operation | Bodies |

Equipment | Modular pressure frame |

Testing conditions |

|

Maximilian Bechert

DB Systemtechnik GmbH

10 Pionierstraße

Minden (Westf)

32423

GERMANY

Shunting test rig

Location | Minden, Pionierstraße 10 |

|---|---|

Operation | Rail vehicles, load securing |

Equipment | Shunting test bed |

Testing conditions |

|

Maximilian Bechert

DB Systemtechnik GmbH

10 Pionierstraße

Minden (Westf)

32423

GERMANY

Screw test rig

| Location | Minden, Pionierstraße 10 |

|---|---|

Operation | Measurement of torques, pre-tensioning force and rotation angle Calculation of friction coefficients |

Equipment |

|

Testing conditions |

|

Peter Heese

DB Systemtechnik GmbH

Betriebsfestigkeit und Simulation

10 Pionierstraße

Minden

32423

GERMANY

Agricultural test rig

| Overview | The load-bearing component structures of agricultural machinery are subjected to high stresses while travelling on the road and in the field. To ensure safe and reliable use by operators, especially during the harvest season, the manufacturers' simulation models can be validated and the design improved through fatigue tests on the laboratory's test rigs. Thanks to state-of-the-art testing technology, both typical operational and individual load and stress scenarios can be realised. |

|---|---|

| Benefits |

|

| Location | Minden, Pionierstrasse 10 |

| Equipment | Load portal and freely selectable load force supports |

Lennart Ruberg

DB Systemtechnik GmbH

10 Pionierstraße

Minden

32423

GERMANY