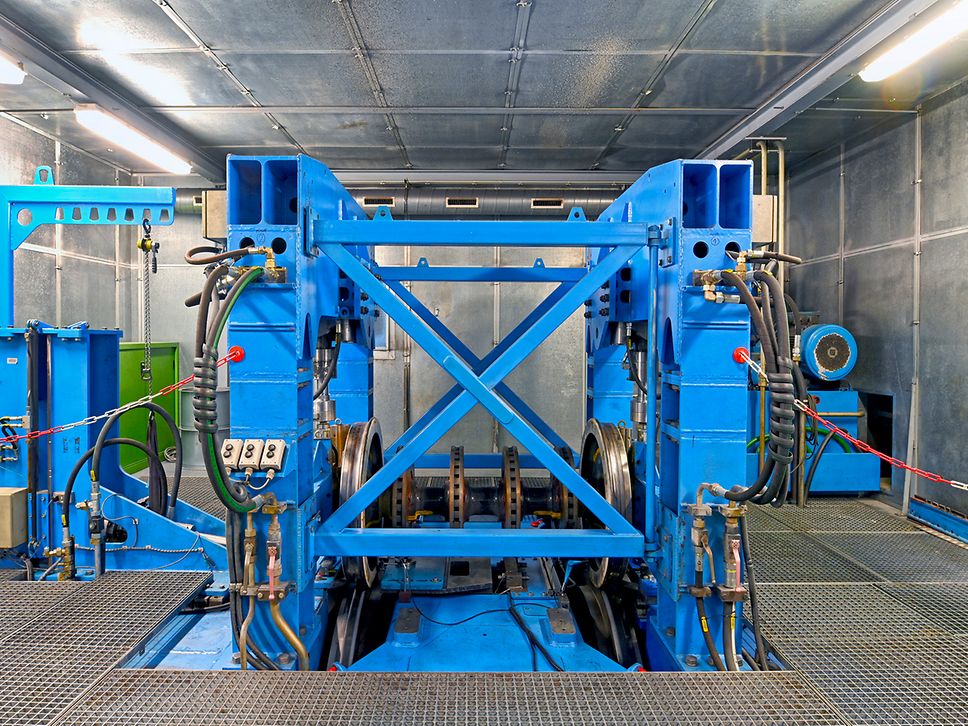

Wheel/rail Test Rig A - Wheelset on Rail Roller

| Location | Kirchmöser, Bahntechnikerring 74 | | Use | Roller rig for investigating wheel/rail contact |

| Focus | Wheel/rail wear- Out-of-round wheels

- Wheel tread damage due to rolling contact fatigue

- Influence of wheel material

- Influence of wheel profile

- Validation and parametrisation of wheel/rail simulation models

- Testing

- Wheel materials

- Wheel profiles

- New developments for non-destructive testing or diagnostic systems

- Friction modifiers

Acoustic measurements- Rolling noise

- Curve squeal

- Influence of wheel noise absorbers

|

| Wheelset | - Non-driven and powered wheelsets

- Wheel diameter: 400 to 1,250 mm

- Material and profile: variable

|

| Rail roller | - Underfloor arrangement

- Diameter 2.1 m

- Rail material: R260

- Rail profile/inclination: 60E2 / 1:40

|

| Parameters | - Axle load: up to 340 kN (34 t)

- Lateral force: up to 30 kN

- Speed: up to 300 km/h

- Curves: from 300 m radius up to ∞

- Lubrication or moistening/irrigation possible

|

Equipment | - Concentricity measurement

- Cross-section measurement

- Axle box accelerometers

- NDT for crack detection

|

Wheel/Rail Test Rig A - Single Wheel on Rail (linear Test unit)

| Location | Kirchmöser, Bahntechnikerring 74 | | Use | Linear test rig for investigating wheel/rail contact |

| Focus | Wheel/rail wear- Cross-section wear

- Rolling contact fatigue (head checks)

- Influence of rail material

- Influence of wheel/rail profile

- Weld joints

- Common crossings / frogs

- Validation and parametrisation of wheel/rail simulation models

Qualification of rails as per DBS 918 254 Testing - Rail materials

- Rail profiles

- New developments for non-destructive testing or diagnostic systems

- Friction modifiers

|

| Wheel | - Wheel diameter: 800 - 920 mm

- Material and profile: variable

|

| Parameters | - 1,000 load cycles/h

- 20,000 gross tonnes/h with 20 t axle load

- Axle load: up to 40 t

- Lateral force: up to 20 kN

- Curves: from 300 m radius up to ∞

- Lubrication or moistening/irrigation possible

|

| Equipment | - 3D geometry measurement

- NDT for crack detection

|

Wheel/rail Test Rig B - Linear Test Rig

Location | Kirchmöser, Bahntechnikerring 74 | Use | Linear test rig for investigating wheel/rail contact when applying longitudinal forces |

| Focus | Wheel/rail wear- Cross-section wear

- Rolling contact fatigue (head checks, squats)

- Influence of wheel/rail material, material pairing

- Influence of wheel/rail profile, profile pairing

- Weld joints

- Validation and parametrisation of wheel/rail wear simulation models

Testing - New rail materials

- Wheel and rail profiles, profile pairing

- New developments for non-destructive testing or diagnostic systems

- Friction modifiers

|

| Wheel | - Wheel diameter: from 640 – 1,250 mm

- Material and profile: variable

|

| Rail | - Length: 1.2 to 1.4 m

- Material and profile: variable

|

| Parameters | - 5,000 load cycles/h

- 100,000 gross tonnes/h at 20 t axle load

- Axle load: up to 40 t

- Longitudinal force: up to 34 kN

- Lateral force: up to 60 kN

- Curves: from 120 m radius up to ∞

- Lubrication or moistening possible

|

Equipment | - Thermography

- 3D geometry measurement

- NDT for crack detection

|

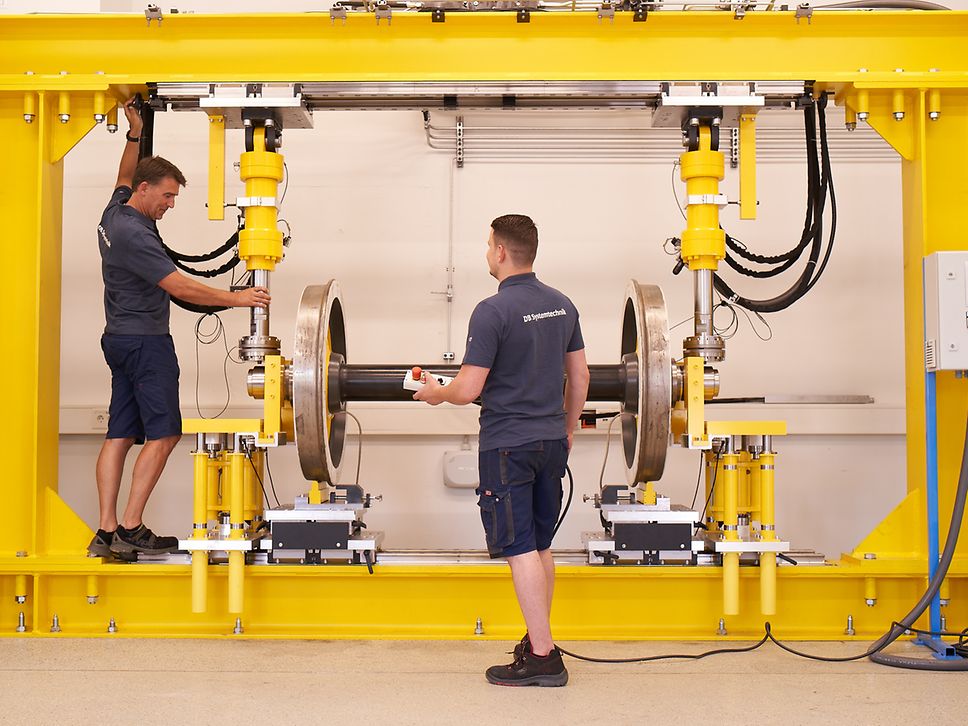

Wheel/Rail Test Rig C - Wheelset on Rail Roller

| Location | Kirchmöser, Bahntechnikerring 74 | Use | Roller rig for wheel and wheelset constructions |

| Focus | Rolling contact tests under real loads- New wheel constructions, also rubber-sprung

- New wheelset constructions

- Variable-gauge wheelsets

- Crack propagation tests on axles

- Testing new developments for non-destructive testing or diagnostic systems

|

Wheel seat | - Non-driven and powered wheelsets

- Wheel diameter: 600 to 1,200 mm

- Profile: cylindrical

- Material: variable

|

| Rail roller | - Underfloor arrangement

- Diameter 2.1 m

- Rail profile: cylindrical

|

| Parameters | - Axle load: up to 340 kN

- Lateral force: up to 80 kN

- Speed: up to 160 km/h

- Programmable load spectrums

|

| Equipment | - Telemetry for strain gauge measurements

- Thermography for rubber-sprung wheel constructions

|

Measuring wheelset

Image: Measuring wheel set - calibration stand in Minden

| Location | Minden, Pionierstraße 10 | Operation | - Determination of the wheel forces Q, the guides Y and the longitudinal forces Tx between wheel and rail.

- Determination of the wheel contact point of the wheel on the rail during the measurement runs.

|

| Equipment | wheelset equipped with strain gauges and inductive telemetry |

Test conditions | Technical driving tests according to EN 14363 or customer requirements |

We support you with your questions about wheel/rail contact