Article: Calculating is better than estimating: Energy consumption measurement on locomotives and multiple units.

In the first quarter of 2020, changes were made to the technical specification for interoperability for locomotives and multiple units (TSI Loc & Pas). In particular, it was then prescribed that an energy measurement system compliant with the European standard EN 50463 be installed on these vehicles.

In the following interview, Iven Billing, engineering expert at DB Systemtechnik, offers an insight into what fleet managers should do

Mr Billing, does every locomotive and every multiple unit have an energy measurement system (EMS) on board and what is its purpose?

Almost every electric locomotive and every electric multiple unit (i.e. with a pantograph) has an EMS. It is used to transmit the energy consumption data about the vehicles to the grid operator, who then calculates the energy costs "down to the last kilowatt".

If no EMS is installed, the energy consumption data is determined by means of estimated values which leads to higher costs.

Do these EMSs only record the energy consumed or also the "regenerative" energy?

Both are recorded by the grid operator. This means that you have to pay for the energy you consume, and the grid operator gives you a "credit" *** for the energy fed back into the grid.

***For vehicles that are put into operation from January 1st, 2023, the proportion of cost reimbursement from the feed-back for the part of the grid fees avoided is reduced.

And why do these EMSs have to be replaced now?

At the end of 2023, Telekom will switch off the circuit-switched data (CSD) transmission technology. This technology has been used since the 1990s to transmit data to the GSM mobile phone network - including the energy consumption data of the locomotives and multiple units.

This remote data transmission no longer meets today's requirements and therefore the data is now being transferred using LTE transmission technology.

And the consequence of using this new protocol is that the transmission no longer works with the previous EMSs?

Yes. New EMSs must be procured and integrated into the locomotives and multiple units.

Is it also possible not to replace the existing EMSs and run locomotives and multiple units without a new EMS?

Of course it is. However, vehicle keepers will then incur higher costs due to the estimated value procedure already mentioned. Nor will there be any remuneration for energy fed back into the grid.

So replacement is worthwhile?

Yes, based on cost savings alone, this is our recommendation. As DB Systemtechnik, we can advise vehicle keepers individually on how to achieve this for each class.

How does DB Systemtechnik help in concrete terms? Is there a model solution?

We are currently supporting large vehicle keepers with the conversion of vehicle classes to the new energy measurement systems.

With this consultation and the technical support, we now have something like a "model solution" under our belt. Meaning that this "EMS conversion" solution is applicable for every electric locomotive and every multiple unit.

Can you list your services and how you support them?

The procurement of the hardware and the conversion of the vehicles remains the responsibility of the vehicle keeper. However, we support them in procurement and especially in the actual technical implementation, as the following services show:

Appraising the situation

- Checking the installation situation

- Checking the continued use of the installed components on the vehicle (e.g. transducer)

Engineering

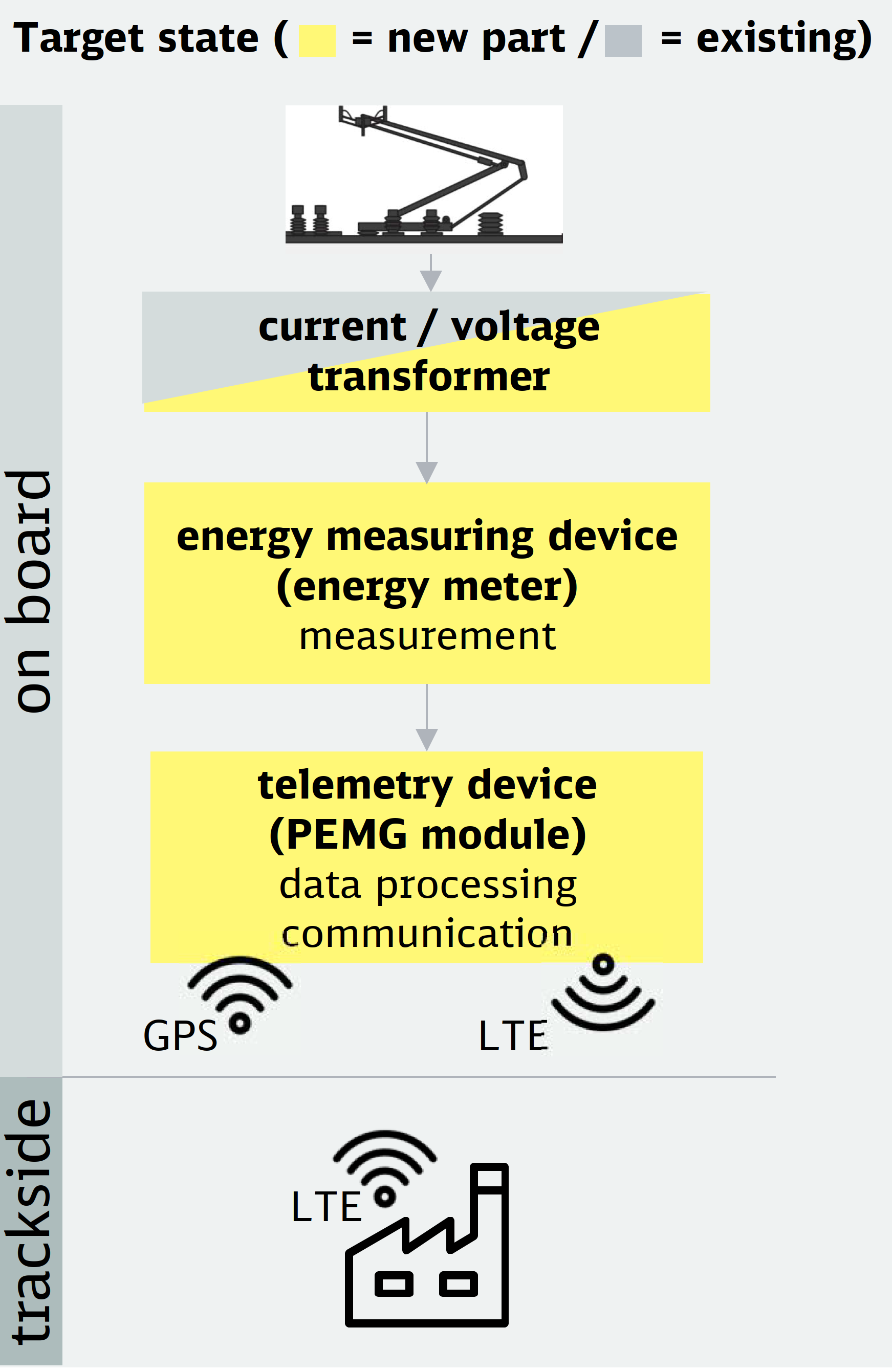

- Integration of the components for the energy calculation and data processing function

- Integration of the positioning function via GPS

- Integration of the communication function by means of LTE

- Substitution of components on the vehicle that cannot continue to be used (e.g. transducers) *)

Procurement support

- Preparation of the necessary documents for the procurement of all necessary components

Approval*

- Verification documentation according to TSI Loc&Pas and NNTR (e.g. mass, strength, fire protection, EMC)

- Supporting ECM in carrying out certification with NoBo and DeBo

Implementation support

- Accompanying production planning and conversion

Who can vehicle keepers contact for further questions?

They are welcome to contact me or Hassan Benaich, my colleague from the Sales Team.