Article: New Shell axlebox greases undergo approval testing by DB Systemtechnik

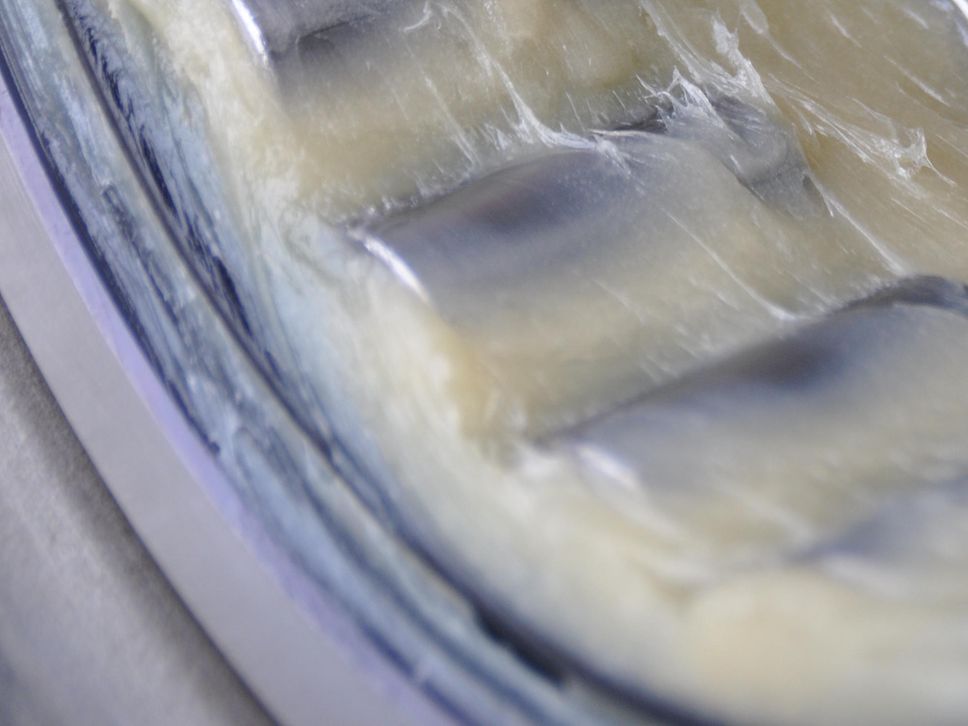

A grease's suitability as an axlebox lubricant is proven by means of physical-chemical testing on mechanical and tribological test rigs and in field tests.

(Munnich, Minden, März 2023) Axlebox lubrication is one of the most sensitive fields of tribology and absolutely vital for the safe transportation of people and goods. That's why DB Systemtechnik tests the basic suitability of new greases for use throughout the DB Group.Axlebox lubrication is one of the most sensitive fields of tribology and absolutely vital for the safe transportation of people and goods.

That's why DB Systemtechnik tests the basic suitability of new greases for use throughout the DB Group.

A grease's suitability as an axlebox lubricant is proven by means of physical-chemical testing on mechanical and tribological test rigs and in field tests.

The new greases developed by Shell will have to pass these stringent quality tests before they can be used to lubricate the axles of wheelsets on rail vehicles used by Deutsche Bahn (high-speed trains, multiple units, freight wagons, passenger carriages and locomotives).

Quality criteria: ultimate mechanical stability and longer service life

The specialists at DB Systemtechnik GmbH set up a special multi-stage test programme for the collaboration with Shell. They based the test programme on European standards EN 12081 and EN 12082, which set out the requirements for chemical-physical, tribological performance tests on the test rig for axleboxes and their lubricating greases, and the exacting standards of Deutsche Bahn guideline DBS 918 310-01, which deals with technical specifications and approval procedures for lubricants and axlebox greases. These documents specify the requirements for the use of axlebox greases at Deutsche Bahn.

The Munich-based tribology team and Minden-based fatigue testing and wheelsets teams responsible for performing the approval tests are curious to see how the new greases from Shell will perform.

Thomas Köhler, head of tribology: "The greases will have gone through laboratory and tribological testing in our Munich tribology lab in the first quarter of 2023. The greases from the same production batch from Ghent will then be tested on the wheelset axlebox test rig in Minden as part of the performance test. After successfully passing all the rig tests, the greases will still have to prove their performance in a field test."

The rest of the programme at a glance:

- Completion of tribological testing in Munich (fulfilment of all requirements set out in EN 12081 and the relevant section of DBS 918 310-01)

- Long-term testing on the axlebox test rig in Minden from January 2023 until the end of 2024 (fulfilment of all requirements set out in EN 12082 and the relevant section of DBS 918 310-01 (e.g. top speed of 363 km/h, maximum mileage of 800,000 km)

- Practical field test depending on use (high-speed trains, multiple units, freight wagons, passenger carriages and locomotives)

Once the axlebox greases have successfully passed all the tests, they will be approved for use by Deutsche Bahn AG for their intended purpose. The quality of the series production of the greases will be monitored by batch testing at the tribology department in Munich.